Boeing Improves Operations with Blockchain and the Internet of Things

Aviation adopts IoT and blockchain

Recently, we’ve posted a story about the potential of combining the blockchain technology and IoT into an IoT-driven blockchain. This combination is being recognized as a winning adoption by the aviation industry. In that story, we highlighted the industries and scenarios that could benefit from the merging of the two technologies.

One such use case is in manufacturing, specifically for parts life cycle tracking and maintenance, where an IoT-driven blockchain could be used to track individual part provenance from the manufacturing date all the way to disposal.

A couple of months ago in IBM InterConnect and more recently at the Internet of Things World, Boeing’s Robert Rencher talked about how the aircraft manufacturer was using IoT-driven blockchains to bolster their aviation ecosystem from asset management to customer transparency.

“We continue to see opportunities in operational efficiencies throughout the aviation ecosystem. A key to this is improving the trust in data utilization across the ecosystem.” —Robert Rencher, Boeing

A life cycle of an aircraft

To better understand how the technology can help Boeing, we first have to look at how aircraft assembly works.

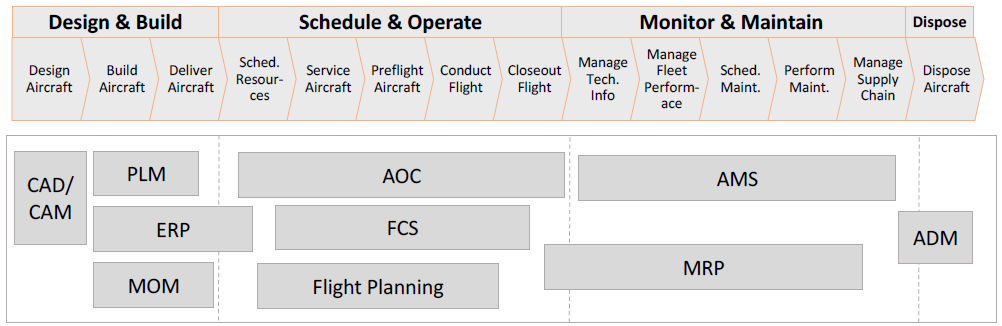

Image credit

Image creditIn the diagram above, we can see that there are four key phases—design and build, schedule and operate, monitor and maintain, and dispose—and each of this phases have steps assigned to them:

- Design and build

- Product life cycle management

- Enterprise requirements planning

- Manufacturing operations management

- Schedule and operate

- Airline operations center

- Flight control system

- Flight planning

- Monitor and maintain

- Aircraft maintenance systems

- Materials requirements planning

- Dispose

- Aircraft demolition management

In each of these steps, thousands upon thousands of individual parts are involved, so tracking each and every one along with maintaining a record of its conditions becomes a challenge.

Where do IoT-driven blockchains come in? According to Robert, “the main value proposition is the reduction of outages and unplanned maintenance.”

Currently, the provenance of each component part in the life cycle of an aircraft is hard to track. This contributes to the complexities that arise in the operation, maintenance, and the eventual disposal of each individual plane. (We have already written about Everledger and the importance of provenance.)

“The generation, collection, dissemination, and accuracy of this information is currently a huge challenge in our industry.” —Robert Rencher, Boeing

What changes with an IoT-driven blockchain?

With blockchain, Boeing holds complete provenance details of each component part. This information is then accessible by each manufacturer in the production process, the aircraft owners and maintainers, and government regulators.

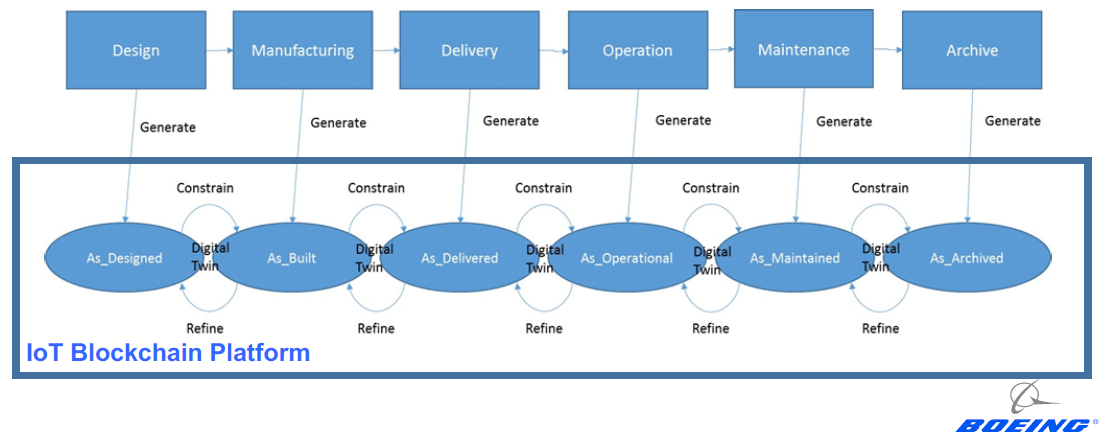

Image credit

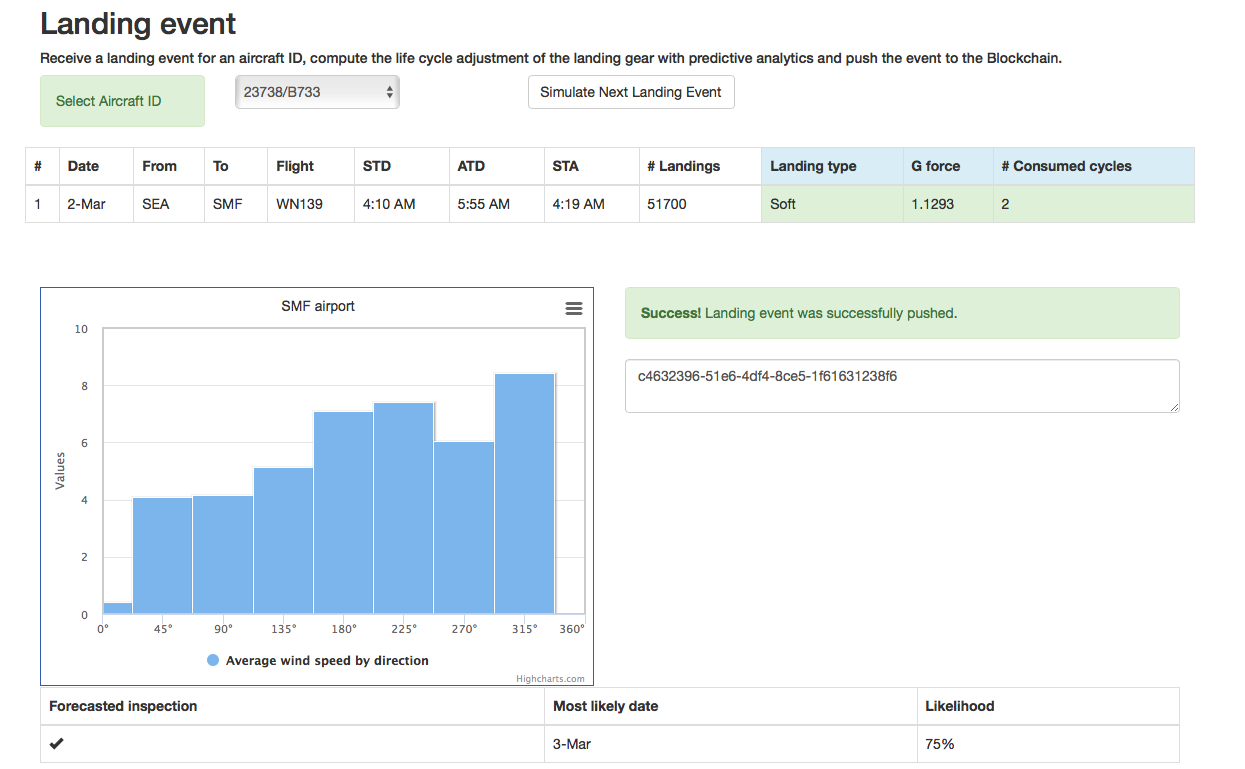

Image creditHere’s we can see how the IoT-driven blockchain will work with the aircraft’s digital twin to anticipate and mitigate problems before they occur.

“The IoT will give us a quicker, deeper understanding of the intimate details of the machines,” said Robert. “We’ll be able to apply predictive analytics to anticipate when there’s going to a problem, and either mitigating the problem or preventing it from happening through technological means.”

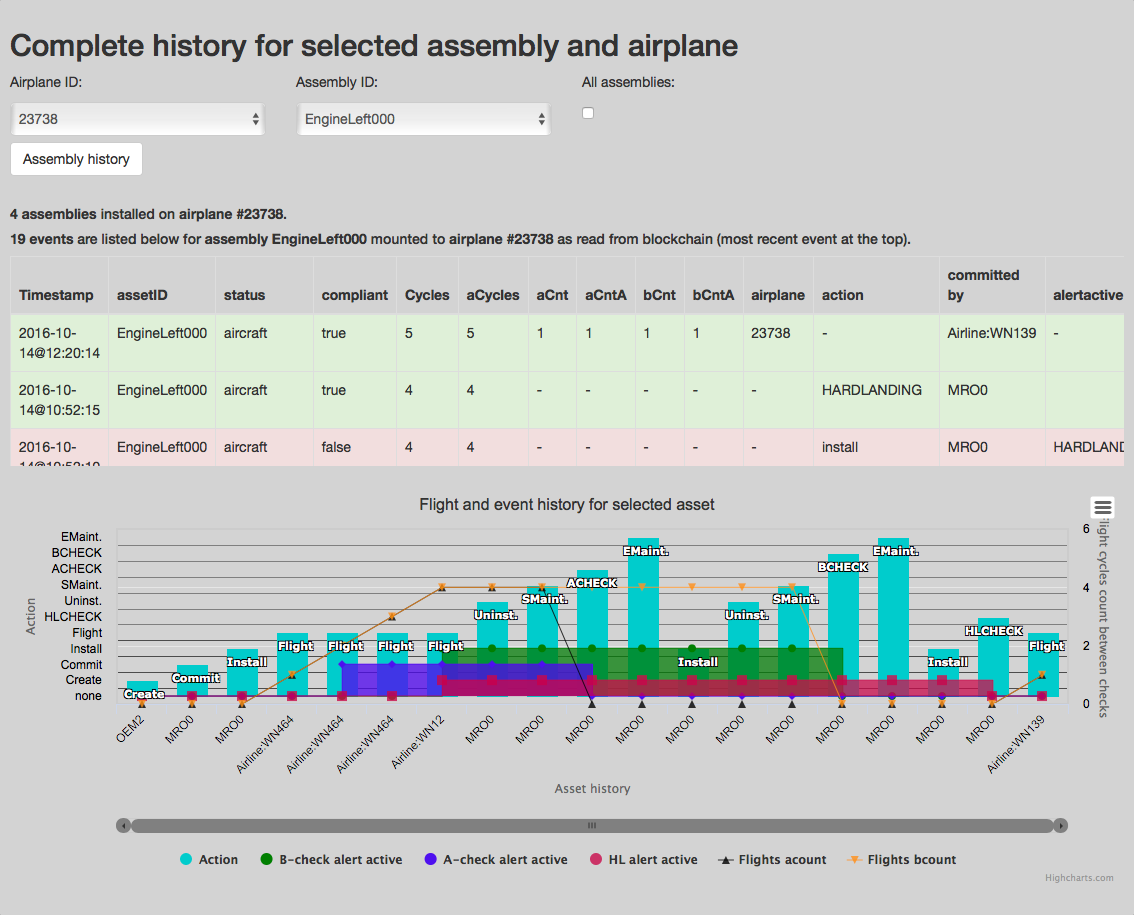

Image credit

Image creditWith complete provenance and IoT, operations will be able to:

- Predict maintenance events

- Optimize production operations

- Extend the life cycle of components

- Customize maintenance for components

“IoT can increase awareness of what’s available from whom, and enhance the accuracy of when new parts are delivered, tackling what is a huge logistical challenge,” said Robert.

“IoT will also help with forecasting demand and rate of consumption, in terms of what the equipment manufacturers are supplying.” —Robert Rencher, Boeing

This concept of predictive maintenance was echoed by Boeing’s John Herpy in a paper published by Ernst & Young. “We can track an aircraft’s position and its in-flight performance,” said John. “When it lands, we can use this data to have the right parts and maintenance capabilities in place to minimize aircraft turnaround time.”

Beyond assembly lines

The efficiencies brought about by IoT-driven blockchains extend from just the manufacturing process. According to Robert, “IoT will also enhance the efficiency of the airplanes themselves. Today, for the most part, the navigation systems are making sure the plane is at the right place, at the right time, and at the right altitude.”

Image credit

Image credit“Think about extending that concept to the performance of the engines, taking in more weather information and so on. We’ll end up with a much greater awareness about the machines and how they’re operating.” —Robert Rencher, Boeing

According to the article, Boeing 777 and 787 use byzantine-proof algorithms that convert environmental data to movements of a flight control surface, for instance.

As far as data generation goes, Boeing planes already generate a huge amount of data as John explains. “The Boeing 787 generates one half terabyte of data for each flight. You can see online how many 787s are in flight,” said John. “Using 200 as a number of active flights, that’s 100 terabytes of data for each of the flights. These aircraft fly two to three flights a day. That’s over a petabyte a week for those 787 aircraft.”

With an IoT-driven blockchain holding all the information, the opportunity for customer transparency is there. “Informed passengers will be the biggest business opportunity,” said Robert. “IoT brings transparency of service. Individuals will have greater selection of services and be responsive to alternatives in opportunities and avoidance of disruption.”

Robert also believes that this will also reach other areas in the aviation industry to make them much more efficient. You can also check out his presentation from IBM InterConnect.

This is already proving true. In 2016, the International Air Transport Association mandated improved baggage claims with IoT initiatives. Where else will we see improvement next?

Related videos

Boeing and IBM have been partners for over a decade now. Here are some of their previous collaborations.

Related reading

- IBM Aims to Improve Manufacturing and Supply Chain with IoT-Driven Blockchains

- IoT for Airlines: Smart Baggage Tracking with RFID Tags and Cloud Foundry

- IBM: Blockchain to Transform IoT, Supply Chains, and the World Around Us

- Decentralized Blockchain as a Solution to IoT Security